The change of press dies more and more is done by die change carts, especially in case of big and heavy press dies. This development is caused by reason of requested work safety during die change, possible time savings, and repeatability of work process, availability of overhead crane or forklift truck as well as specific space conditions at site.

The product range of Hedin India regarding die change carts comprehends: + Front loading versions with short lifting stroke + Side loading versions with short lifting stroke

The Die Change Carts consists of a standardized drive unit and a customer-specific adopted load pick up. + Available from 5 up to 100 ton or more. + Docking to the press Very strong Push/Pull device + Pedestrian Walk beside the cart with the Radio + Small footprint - small turning radius + Emission free electrical drive + No counterweight - light weight + Radio Remote control + Safe and accurate movement + Made out of standard components + Tailor made design and measures to fit your needs.

Adopting of the load pick up to the customer-specific situation at site is necessary, as the drive in situation, the docking possibility as well as the press design are different from press to press. The situation of storing of press dies into corresponding storage racks also is totally different from customer to customer.

On the following pages you will find the detailed descriptions of the different Die Change Carts WWF. If you will have questions regarding our Die Change Carts WWF, we will be at your disposal at any time. Please do not hesitate to contact us.

40 ton Die Change Truck

25 ton tool Change Cart

+ Front loading versions with long lifting stroke via mast + Front loading versions with long lifting stroke via lifting scissor

Hedin Tool Change Carts.

Available from 5 up to 100 ton or more.

Docking to the press

Very strong Push/Pull device

Pedestrian Walk beside the cart with the Radio

Small footprint - small turning radius

Emission free electrical drive

No counterweight - light weight

Radio Remote control

Safe and accurate movement

Made out of standard components

Tailor made design and measures to fit your needs.Read More >>

25 ton Die Change Truck with a 2.5 m lift

10 ton Tool Change Cart with a scissor table lift

To change press dies without support by Die Lifters with rolls needs, depending on the weight of the press die, very strong forces. Thereby already the change of smaller press dies by the operator is a show of strength. To change bigger press dies without support by Die Lifters with rolls or balls is nearly impossible.

Die Lifters with Balls allow a multi-directional movement of the die and give the bestpossible manoeuvrability. Caused by their smaller load capacity as well as their punctual contact to the press die (increased wear at the bearing surface at the bottom side of the press die) they normally are used in case of smaller die weight only.Read More >>

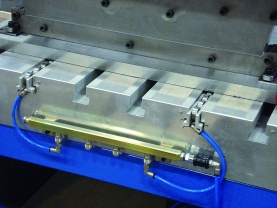

Pneumatic Die Lifters

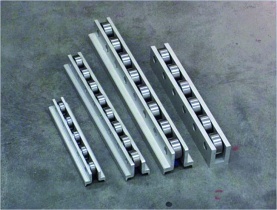

Die Rollers for all sizes of T slots

Stationary Die Change Tables manually and with Die Mover (motorized)

Stationary Die Change Tables usually are installed at the rear side of the press and are designed as a T-shape.

this type of construction allows the operator to deliver the next press die earlier, whilst the the old press die still is working within the press.

As soon as the old die is pulled out of the press and pushed onto the free side of the T-shaped Die Change Table, the new prepared die can be moved sidewards up to the front of the press table. After that it can be pushed into the press immeadiatly.

T Table / Die Change Table Manual Push/Pull

Motorized Die Change Table for heavier Tools